Here’s why Magno is the graphic paper still on top of the pile – 45 years on

It’s hard to believe that Magno was first launched in 1980 – but in today’s print market, its benefits have never been more relevant

Today’s print market has never been more demanding. Not least because customers choosing print require graphic papers that can deliver big – on multiple fronts. Quality, performance, reliability and sustainability are all sizeable boxes that need to be ticked when selecting the right paper for your customer’s next print job.

This year marks 45 years since a paper was launched that has lived up to the challenges of a rollercoaster print market ever since. Thanks to consistent and continuing Sappi investment and innovation, Magno continues to tick those big boxes, time after time.

It all starts with quality and reliability

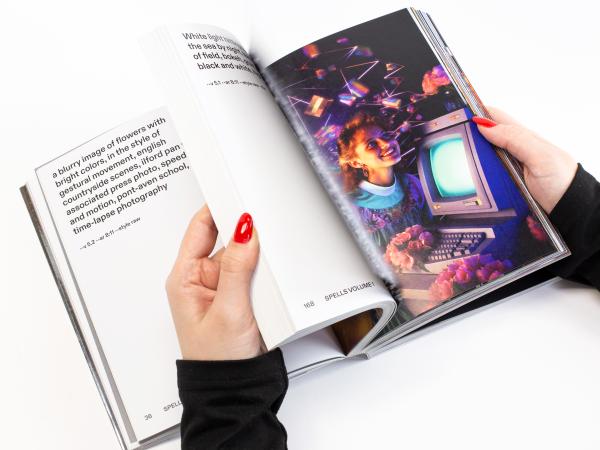

As Magno’s product range has increased – from tktkt paper options in 1980 to nine today, available in both reels and sheets – its technical performance and sheer reader-experienced quality have steadily improved. So it’s no surprise that – backed by Sappi’s network of on-the-ground local sales offices – Magno has become the paper of choice for premium magazines, hard-working catalogues and high-impact mailings across Europe.

Produced at our mills in Kirkniemi (Finland), Gratkorn (Austria) and Maastricht (Netherlands), among others, those papers come with security of supply guaranteed. And at a time when being able to tell print customers a convincing sustainability story has never been more important, modern Magno comes with serious sustainability credentials too.

A new chapter in sustainability

At Kirkniemi, investment in state-of-the-art facilities and a switch to the use of biofuels for all production has meant a massive 90% cut in direct fossil greenhouse gas emissions (Scope 1 emissions).

At the Gratkorn mill, a complete overhaul of the boiler system – now running on biomass and natural gas – has reduced emissions by 30% and raised the share of renewable energy to more than 56%.

Meanwhile at Maastricht, electric steam boilers have been introduced, designed to run when renewable electricity is available, that are expected to slash the mills CO2 emissions by a third within five years.

A paper fit for the future

With print having to become ever more agile and adaptable to compete in the modern media mix, today’s best graphic papers have to show they can perform when run through the most modern, demanding print machines.

That’s why, last year, Sappi conducted real-world tests to compare the performance of Mago Web with its main competitors in heat-set web offset printing.

The results? Magno Web Gloss and Magno Web Silk came out top of the class in the tests, outperforming competitors in bulk, stiffness and opacity as well as consistency – over the full range of grammages.

Magno Web also emerged as a stand-out choice for high-speed inkjet printing when tested, too.

All this means that printers and printer customers can and rely on one high-performance paper for both heat-set web offset and high-speed inkjet printing.

And it means end-products offering a premium feel alongside superb colours, excellent readability and the highest of printability standards. Not forgetting superb sustainability credentials that meet the highest industry standards.